The Quest for Excellence in Garment Manufacturing

In apparel manufacturing, the pursuit of efficiency, innovation, and quality is constant. As designers sketch the future of fashion, the real magic happens on the production floor where ideas transform into tangible products. But how do we refine this complex process? In this blog, we’ll stitch together insights and strategies to enhance garment manufacturing, ensuring that every thread leads to success.

Unraveling the Fabric of Apparel Manufacturing

The Backbone of Fashion: Understanding the Process

Before diving into improvements, let’s unfold the manufacturing process of apparel. It’s a journey from concept to creation, encompassing six key steps:

- Designing: A fusion of creativity and market trends.

- Pattern Making: Translating sketches into blueprints for production.

- Sourcing Materials: Selecting fabrics and trims that embody quality and sustainability.

- Cutting and Stitching: The heart of manufacturing, where precision meets artistry.

- Quality Checks and Finishing: Ensuring every garment meets the high standards of the fashion world.

- Packaging and Distribution: The final step, sending off the creations to meet their new owners.

Tailoring Success: 4 Ways to Elevate Production

Innovate, Optimize, Automate, and Collaborate

- Embrace Technological Innovation: Incorporating advanced technology like 3D printing and AI-driven pattern making can revolutionize the design and sampling phases, saving time and resources.

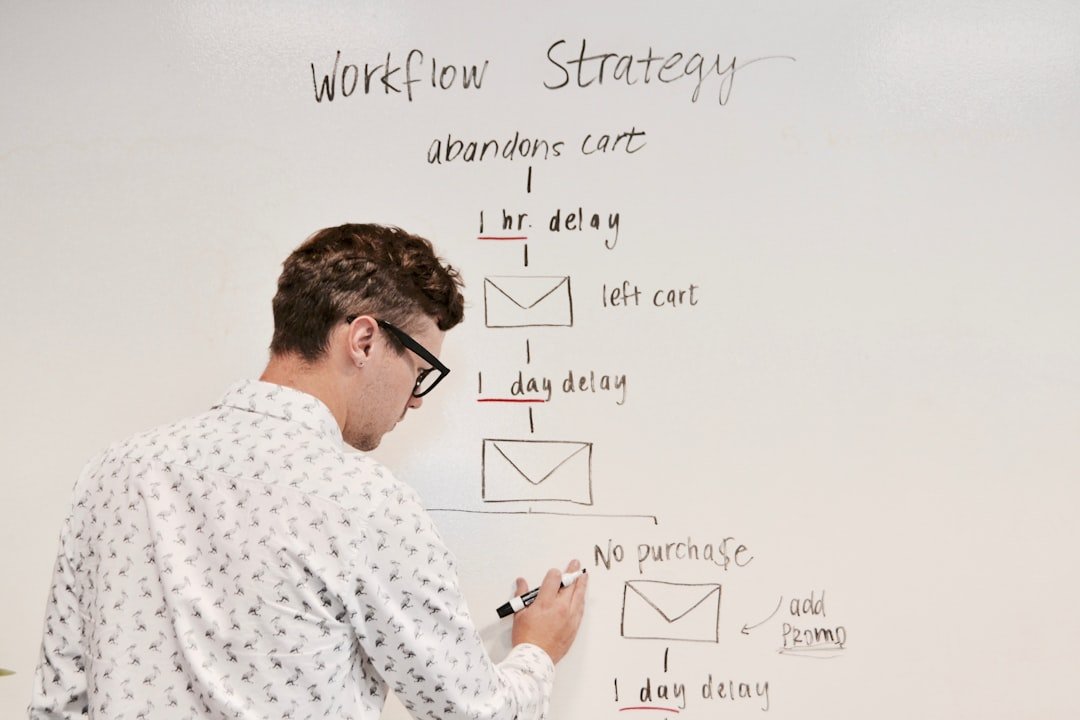

- Streamline with Lean Manufacturing: Adopting lean principles can significantly reduce waste and increase efficiency. It’s about doing more with less, without compromising on quality.

- Invest in Automation: From automated cutting machines to AI-powered quality control, automation not only speeds up the production but also ensures precision and consistency.

- Foster Collaborative Partnerships: Building strong relationships with suppliers and embracing collaborative practices can lead to more innovative, sustainable, and cost-effective production methods.

Crafting Excellence: The Heart of Apparel Manufacturing

The Human Touch in a Mechanized World

In an industry often criticized for its environmental footprint and labor practices, bringing a human touch to the process is vital.It’s important to establish a work environment that values the individuals crafting each garment, upholding fair labor practices and fostering a culture of respect and creativity. This ethical approach doesn’t just build better products; it builds a better world.

Conclusion: Sewing the Future of Fashion

Weaving Innovation with Tradition

The path to improving garment manufacturing is not just about the latest machines or software. It’s about harmonizing innovation with the rich traditions of the apparel industry. It’s about understanding that at the heart of every garment, there’s a story—a story of creativity, precision, and human touch.

In the vibrant tapestry of the apparel industry, every thread counts. By adopting these strategies, manufacturers can not only enhance their production processes but also contribute positively to the global narrative of sustainable and ethical fashion.

Join Us on this journey of transformation, where every stitch is a step towards a more efficient, innovative, and humane apparel industry.

5 replies on “Streamlining Apparel Manufacturing: Innovations and Strategies for Optimal Production”

[…] their production processes and deliver better products to their customers. Check out the article here for more […]

[…] that delves into the intricacies of modern manufacturing and workspace optimization is available at Modern Apparel Manufacturing Workspace. This piece highlights how strategic planning in manufacturing environments can significantly […]

[…] As companies increasingly recognize the importance of product governance, it is becoming a critical focus for board members. This shift is driven by the need for greater accountability and transparency in product development and management. A related article discusses the evolution of modern apparel manufacturing and how it aligns with these governance principles, highlighting the significance of sustainable practices and ethical sourcing in today’s market. For more insights on this topic, you can read the article on modern apparel manufacturing. […]

[…] For more insights on this topic, you can read the article on modern apparel manufacturing here. Understanding these trends will be crucial for businesses aiming to meet the demands of the next […]

[…] You can read more about this fascinating intersection of technology and industry in the article on modern apparel manufacturing. This highlights the broader impact of AI across various sectors, showcasing its potential to […]